The operating room is an extremely demanding work environment, with project goals often defined as life itself at stake. Utmost care must be taken to ensure that all tools involved in the process, protective garments and drapes included, support the optimal success of the mission. GD’s surgical gowns and drapes are made of technologically advanced textiles that provide comfort, breathability and protection. The reusable garments are highly durable, liquid repellent, and shield both medical staff and patients from bacterial contamination. Hospitals all over the world continually aim to reduce costs while raising medical standards. Studies consistently show that reusable operating room garments surpass disposables in terms of strength, liquid absorption and bacterial protection.

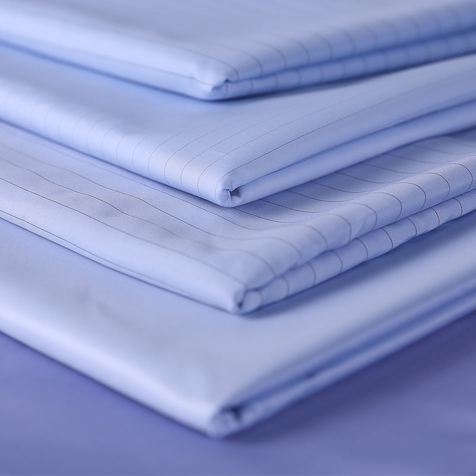

GD’s surgical gowns and operating room patient drapes are made of leading European Tri-laminate producers, which abide by industry standards including EN13795, ASTM1670 and ASTM1671, even after 70 wash, dry and autoclave cycles.

Our Tr–laminates provide complete resistance to penetration by blood, other liquids and germs, and help prevent the transfer of contaminants from medical staff to patients and vice versa. Gowns are soft to the touch and lightweight, and comfortable due to their breathability which also allows heat and sweat to escape. Their resilient durability and reusability make the gowns highly cost-effective. Two of the world’s leading polyester fabric producers, Hyosung Corporation and Teijin, manufacture our base and back panel material for gowns and drapes.

GD manufacturing facility for operating room textiles is certified ISO-13485 for production of medical devices. The efficient plant allows us to provide on-demand production of a variety of textile products at particularly small quantities.